Effective and cost efficient disinfection or sterilizing of surfaces, water and objects can have a significant, positive effect on the general health of our society. The impact of pandemics can be greatly reduced, as well as a major decrease of illnesses in general, including from drug resistant pathogens or hospital-acquired infections (HAI).

Disinfection or sterilization with ultraviolet (UV) light can be the way to achieve such goals. However, challenges of using UV light still exist and the ways to overcome them are presented in this article.

|

"UV light annihilates viruses and bacteria by destroying their ability to reproduce. "

|

Using ultraviolet (UV) light to disinfect or sterilize1 has actually been embraced by some hospitals since years, by using large, industrial-grade machines to kill microorganisms (including COVID-19) in hospital rooms or on furniture, objects, clothing or instruments. However, such machines are the perfect showcase of the challenges of using UV light. They are prohibitively expensive for private or business use, as a mobile platform with UV lamps can cost more than 60.000 USD2. Their deep UV radiation is also dangerous for people and must be used only in empty rooms.

With the current advances in UV LED lighting technology both problems can be overcome.

Smaller versions of UV disinfection lamps can be built at affordable cost, so they are accessible to consumers and companies looking to clean pretty much everything, from office spaces, elevators and living rooms, to phones, computers and even toilet seats.

Different UV wavelengths with precise control of intensity and radiation pattern can make disinfection safe to be used when people are present.

How UV light kills viruses and bacteria

Bacteria are one-celled organisms that can be found naturally throughout our bodies and in our environment. Viruses are smaller than bacteria and they attach themselves to another living cell and use that cells' genetic material to reproduce themselves.

Most viruses cause disease, such as COVID-19, the flue, common cold, AIDS, chicken pox and much more. Well known dangerous bacteria are Salmonellae, Staphylococcus Aureus (MRSA) or E.coli.

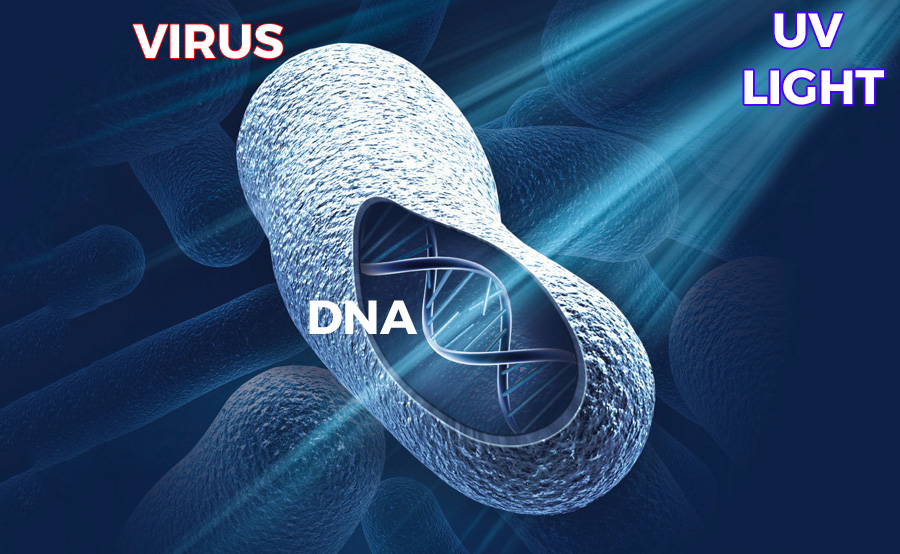

While bacteria and viruses are clearly different, both have a very common attribute, they have genetic material (DNA).

Sunburns, that we have to protect from when out in the sun, happen because UV light damages DNA. This is exactly how UV light can kill all viruses and bacteria, by damaging their DNA3.

A DNA molecule is made of two strands bound together by four bases, adenine (A), cytosine (C), guanine (G), and thymine (T). These bases are like an alphabet, and their sequence forms instructions for cells to reproduce.

UV light can cause thymine bases to fuse together, scrambling the DNA sequence and essentially throwing a wrench into the replication machinery. Since the DNA sequence is no longer correct, it can no longer replicate properly. UV light annihilates viruses and bacteria by destroying their ability to reproduce.

Will it work on the coronavirus?

While COVID-19 is a new virus, the major difference to others is that people do not have immunity to it, as of yet. Exposed to UV light the COVID-19 will die like any other virus. Studies on both SARS4 and MERS proved that UV light kills viruses, so it’s almost certain it will do the same with COVID-19.

Types of UV radiation

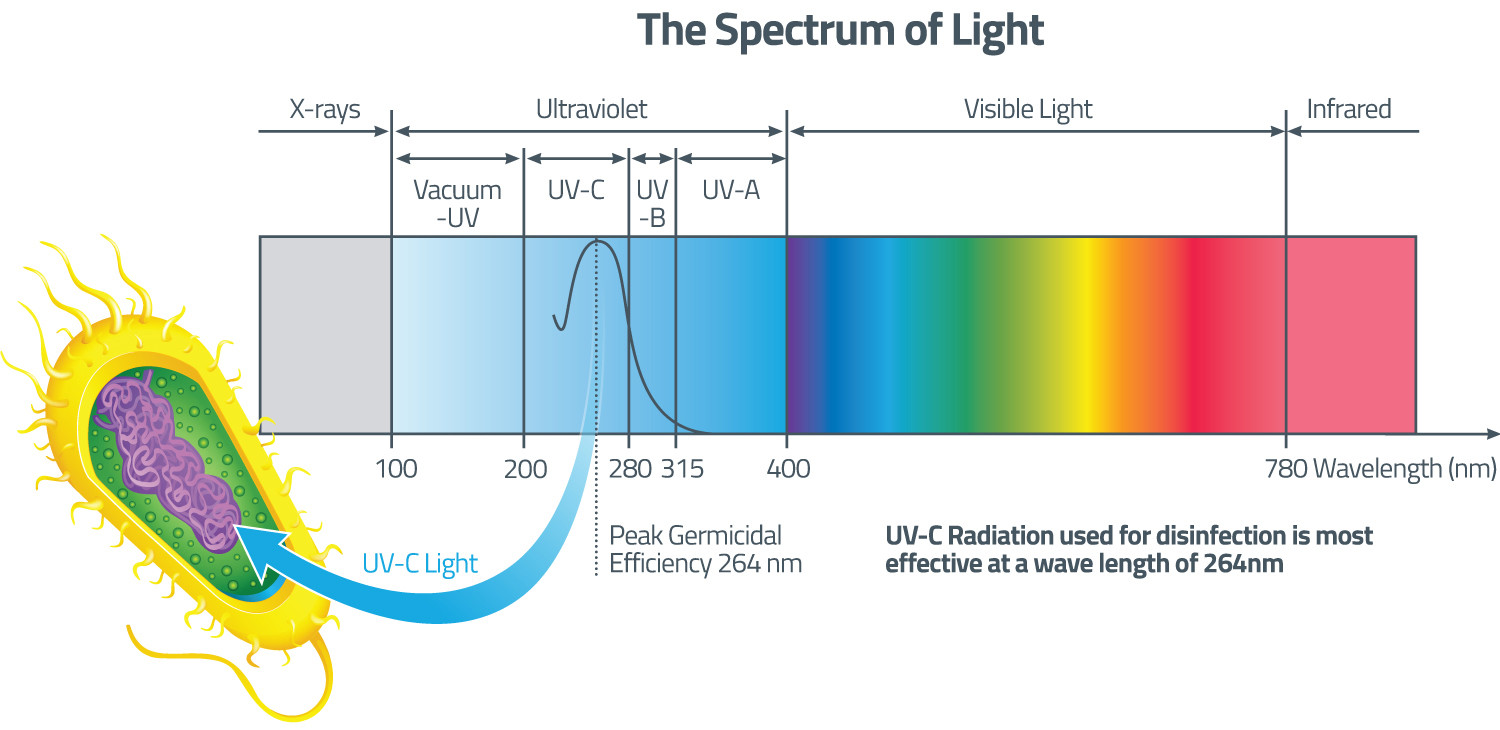

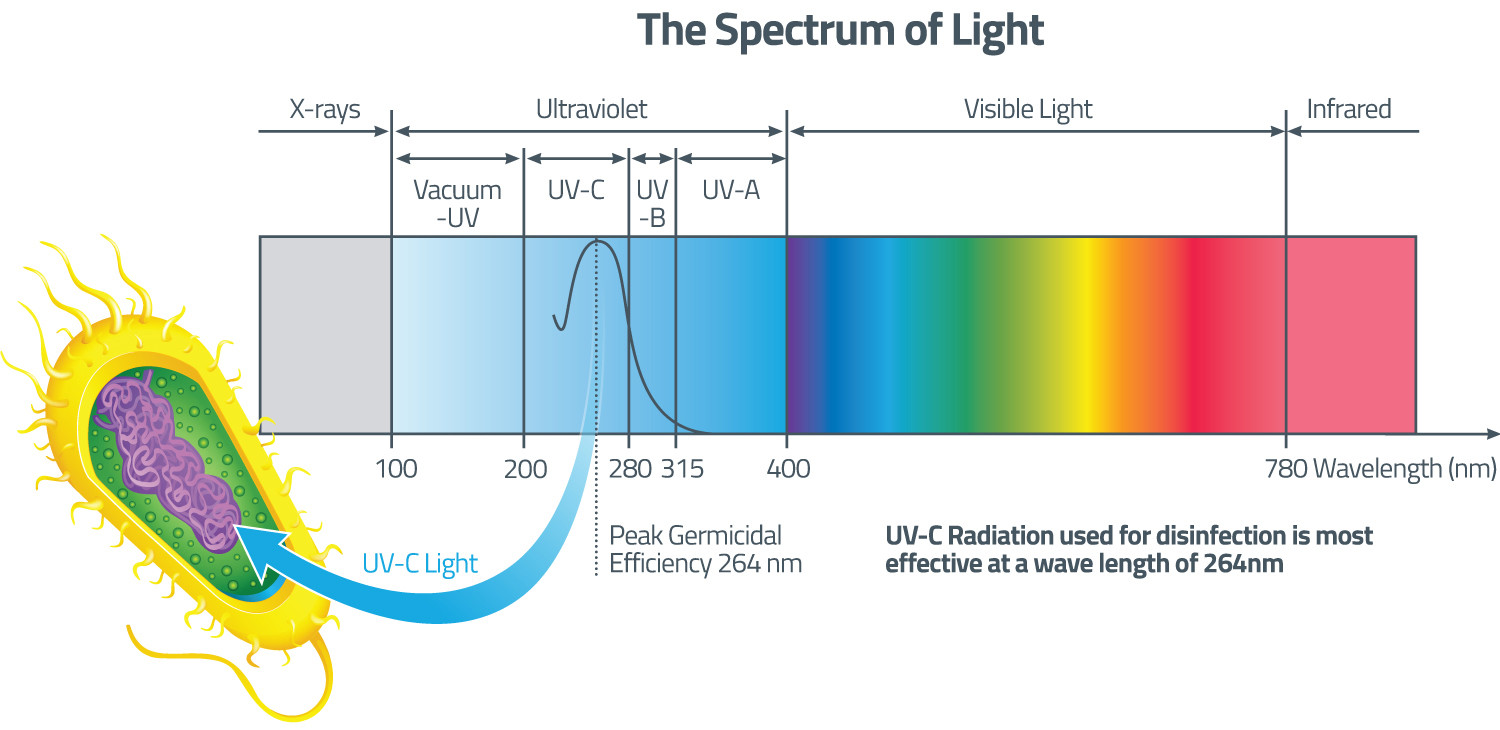

UV is defined as electromagnetic radiation with a wavelength between 100 and 405 nm. Within this interval there are three subintervals that are very important to take into consideration: UVA, UVB and UVC.

According to CIE 1984, CIE 1987:

- UVA light has a wavelength from 315 to 400 nm

- UVB wavelength is from 280 to 315 nm

- UVC wavelength is from 100 to 280 nm

The time needed for UV to kill bacteria or viruses is depended on the radiation wavelength. UVC radiation will require the shortest time, as low a few seconds while UVA with the same irradiance will disinfect in minutes or hours.

The time needed for UV to kill bacteria or viruses is depended on the radiation wavelength. UVC radiation will require the shortest time, as low a few seconds while UVA with the same irradiance will disinfect in minutes or hours.

Unfortunately there is a direct relationship between the rapidity of the sterilisation or disinfection process and the danger to human health. According to international safety standards, such as EU-Directive-2006-25-EC, UVC radiation is the most dangerous, with maximum exposure (depending on wavelength and energy) of only a few seconds.

Disinfection with UVC is currently the most used, including in the expensive robots. For this reason the deployment of UVC lamps is limited, being restricted to tightly controlled, professional use.

Germicidal UVC Lamps explained

UVC lamps that kill viruses and bacteria are called Germicidal UV Lamps.

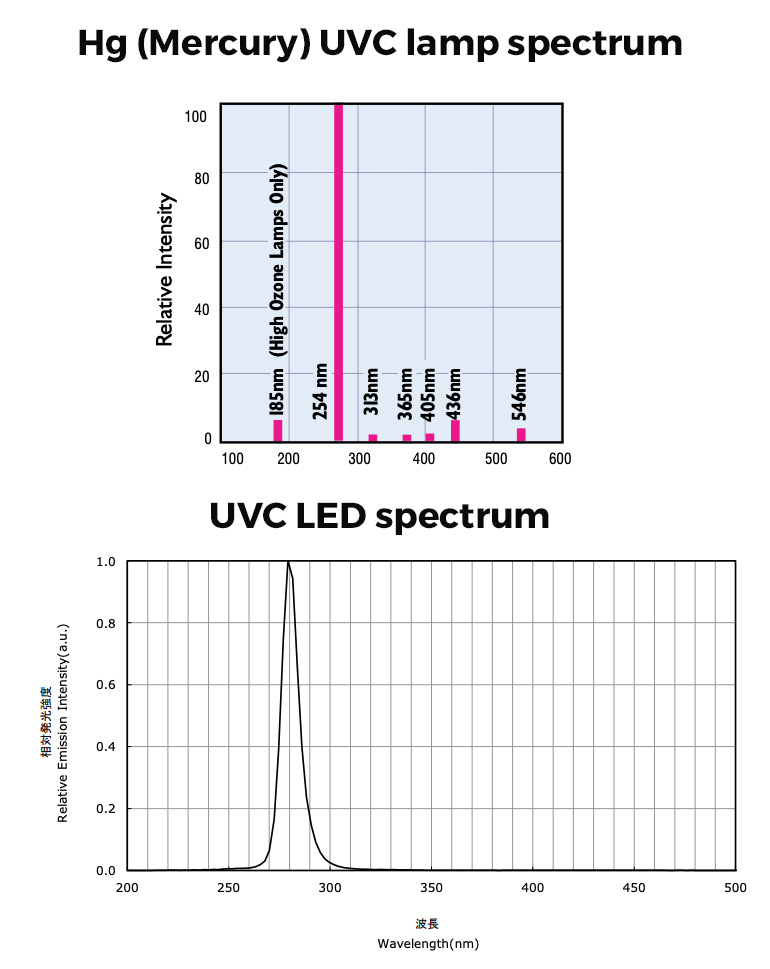

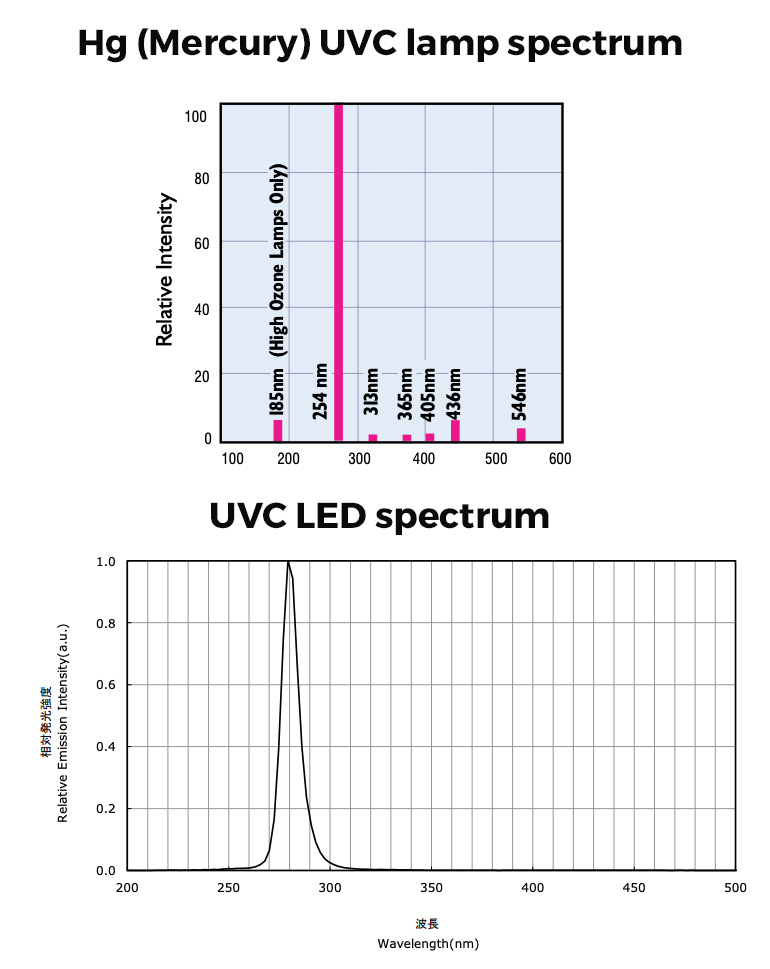

Currently on the market the most common types of Germicidal UV Lamps are Hg lamps with UVC radiation.

Fluorescent tubes are also available with UV light, are referred to as “black lights”, but have other applications such as forensics, decorative light or “bug zappers”, depending on the wavelength peak. Some models of Hg lamps have the same format as T8 fluorescent tubes, which can lead to confusion about the type of lamp.

The most Hg lamps are low and medium pressure mercury (Hg) vapour lamps and they emit UVC radiation with a peak at 254 nm. They can reach high conversion efficiencies, up to 40%, from input electrical power to output UV radiation. However, these lamps are limited in their power density (maximum UV w/m2) and their housing is made of fused silica (quartz), a must for the necessary UV transmission and resistance to the high operating temperature.

As UVC radiation is absorbed and damaging to many materials, including plastics, these lamps are always used without any protection case, making them susceptible to breakage that can lead to mercury contamination.

UVC radiation from our sun is also blocked by the atmosphere so no living organism, including people, have protection from it. It is as dangerous to viruses as to humans, thus lamps with UVC radiation must be deployed with great care. Tiny doses can damage the skin or eyes.

|

"The major differences between germicidal Hg lamps and UVC LEDs are the safety of their use and effectiveness of irradiating UV rays on the surface that needs to be disinfected. "

|

All Hg lamps also have a broad spectrum, with peaks from 185 nm to 546 nm that makes them even more dangerous for people, which restricts the medical application even more. Their radiation is emitted in all directions and cannot be easily focused with a reflector.

UVC light emitting diodes are built to have narrow emission spectrums, such as 265nm, 280nm (see above), 365nm or 385 nm. Many new approaches at disinfecting with light are possible.

The main body of UV-LEDs consists of the semiconducting compounds GaN, InN and AlN and their mixed crystals. When low voltage electric current passes through specially doped layer sequences of these semiconductors, it is partially converted directly into UV radiation.

With such design, UV LEDs are compact and shock resistant. They have no heat in their UV beam and very little overall, so high density arrays can be built. Because a LED has a standard viewing angle of only 120 degrees, much more UV radiation can be directed at a surface.

UVC LEDs also allow for the possibility to use high precision lens (up to 90% efficiency) so the efficiency of a disinfection device can be increased without the need for higher total UV output. The UV output of a LED lamp can be further controlled by regulating the input current with a LED driver.

These major differences compared to germicidal Hg lamps allow UVC LEDs to be designed into disinfection devices that are effective, safe, easy to use and affordable.

The effectiveness of sterilization or disinfection with UVC light depends on the exposure, time, wavelength and irradiance6.

- Exposure or fluence (sometimes called dose) is measured in mJ/cm2 (where 1 mJ/cm2 = 10 J/m2.)

- Exposure time is measured in seconds (s), minutes (m) or hours (h)

- Irradiance is the flux of radiant energy per unit area, in other words how much of the UV radiation power (measured in W = 1000 “miliwatts” mW = 1.000.000,00 “microwatts” μW ) reaches the surface. Irradiance is measured in mW/cm2 or W/m2 (1 mW/cm2 = 10 W/m2) and is dependent on the radiant power, distance and dispersion of the radiation emitted by the lamp source.

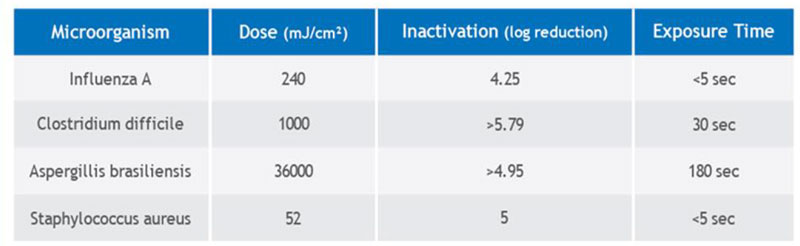

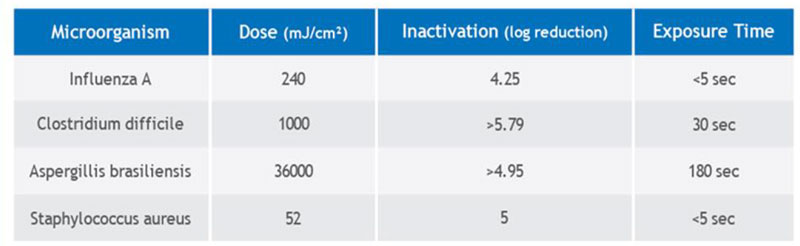

Studies that show the effectiveness of UVC light in disinfection or sterilization present in their findings the inactivation of virus or bacteria for a given Exposure in an amount of time, for a given UV wavelength.

The Exposure (fluence or UV dose in mJ/cm2) is obtained by multiplying the Irradiance (fluence rate in mW/cm2") by the exposure time in seconds. For example for a UV with a Irradiance of 3 W/m2 the exposure for one hour is 10800 J/m2.

Germicidal action of UVC 200-280 nm for rapid disinfection and professional use

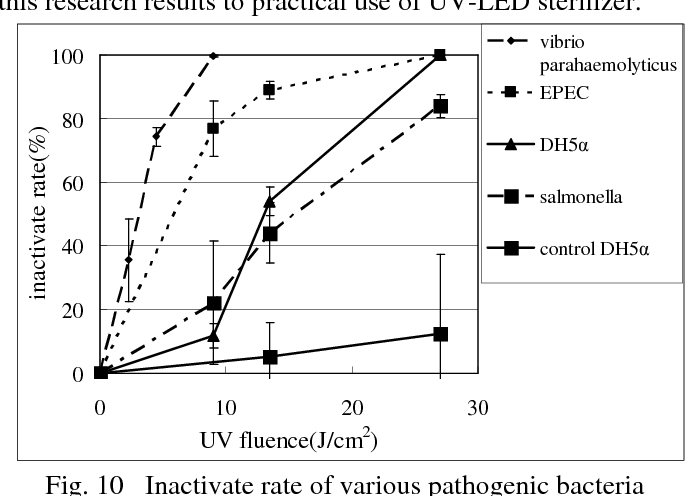

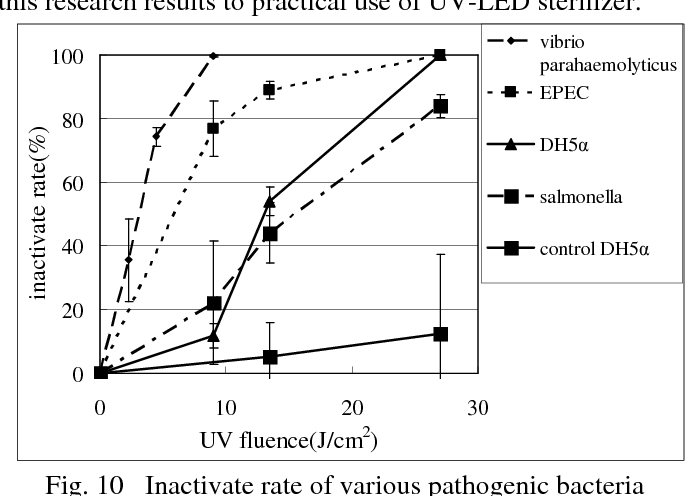

There are many studies 1,3,4,5 about the effectiveness of deploying UVC lamps for disinfection or sterilization, either with Hg lamps or LEDs. For example the results of such a study can be found below:

As explained, the dose depends on irradiance and time.

Example: for a dose of 100 mJ/cm2 in a period of 5 seconds a 100 / 5 = 20 mW/cm2 irradiance is required. If the irradiance is higher, the required dose of 100 mJ/cm2 is reached in less time: at 200 mW/cm2 the time is only half a second, while for 4 mW/cm2 is 25 seconds.

From the analysis of a compilation of 431 studies a fluence of 20 mj/cm2 can achive 90% disinfection for most viruses, bacteria and more, as detalied in the article at this link.

The research cleary shows that UVC lamps in a hospital setting could quickly disinfect surfaces, even in a matter of seconds.

With the recent COVID-19 outbreak UVC lamps where deployed is many hospitals. In China, the latest guideline on the diagnosis and treatment of the novel coronavirus released by the National Health Commission is recommending an irradiance of 1.5 watts per cubic meter to effectively eliminate the virus. A UVC lamp with this intensity can disinfect objects within one meter for at least half an hour.

The studies are the science behind the use of UV lamps for sterilization or disinfection. They are the reason why UVC lamps are used in the way they are, with powerful, short emissions in empty hospital rooms.

Similarly, research presented in this article will bring forward the disinfection with UVA LEDs.

Germicidal action of UVA 365-380 nm for widespread disinfection at affordable price

|

"<10 min & 800mW: Complete germicidal effects of E.coli and Vibrio parahaemolyticus7"

"<60 min & 800mW: Complete germicidal effects for Vibrio parahaemo-lyticus, Staphylococcus aureus, Salmonella enteritidis in water8"

"<5 min & 250mW: 90% eradication of C. albicans and E.coli9"

"<30 min & 1000mW: 99.9% eradication of Candida albicans and Escherichia coli10"

"<60 min & 10mW+1.69mW: Complete germicidal effects of Mesophilic bacteria and Fecal enterococci in 500ml of water11"

|

With the development of the first UVA LEDs in the 2000s, studies about the efficiency of 365 nm in disinfection and sterilization have started to appear. They are the root of concept for continuous disinfection with a summary of the results for several of these studies presented next.

1. The first was a 2007 study7 from Japan, that found that there are complete germicidal effects for E. coli and Vibrio parahaemolyticus by exposure at a 365nm UV-LED for a time of 30 minutes and 10 minutes, respectively. The conclusion came from experiments made with 8 Nichia UVA LEDs NCCU033(T) UV with a radiant power of only 100mW each.

2. The study was followed by research8 into sterilisation of water, with the same 8 LEDs Nichia UVA LEDs NCCU033(T) of 100 mW. All bacteria, Vibrio parahaemo-lyticus, Staphylococcus aureus, Salmonella enteritidis, found in water was 100% eradicated in less than 60 minutes.

3. Evidence increased with a study9 in 2010. By using one Nichia NCSU033A(T) 365nm UV-LED with 250mW from distance of 2 cm the researches concluded that 90% of C. albicans and E.coli is effectively inactivated in under 5 minutes. In 60 minutes no trace of these bacteria was found (>99% kill rate).

4. Surface sterilisation (>99.9% kill rate) in less than 30 minuts was confirmed in another 2010 study10 with 4 x Nichia NCSU033A(T) 365nm UVA LEDs with a radiant power of 250mW each (1000mW). After only 5 minutes, 90% of microorganisms, (Candida albicans and Escherichia coli), where gone.

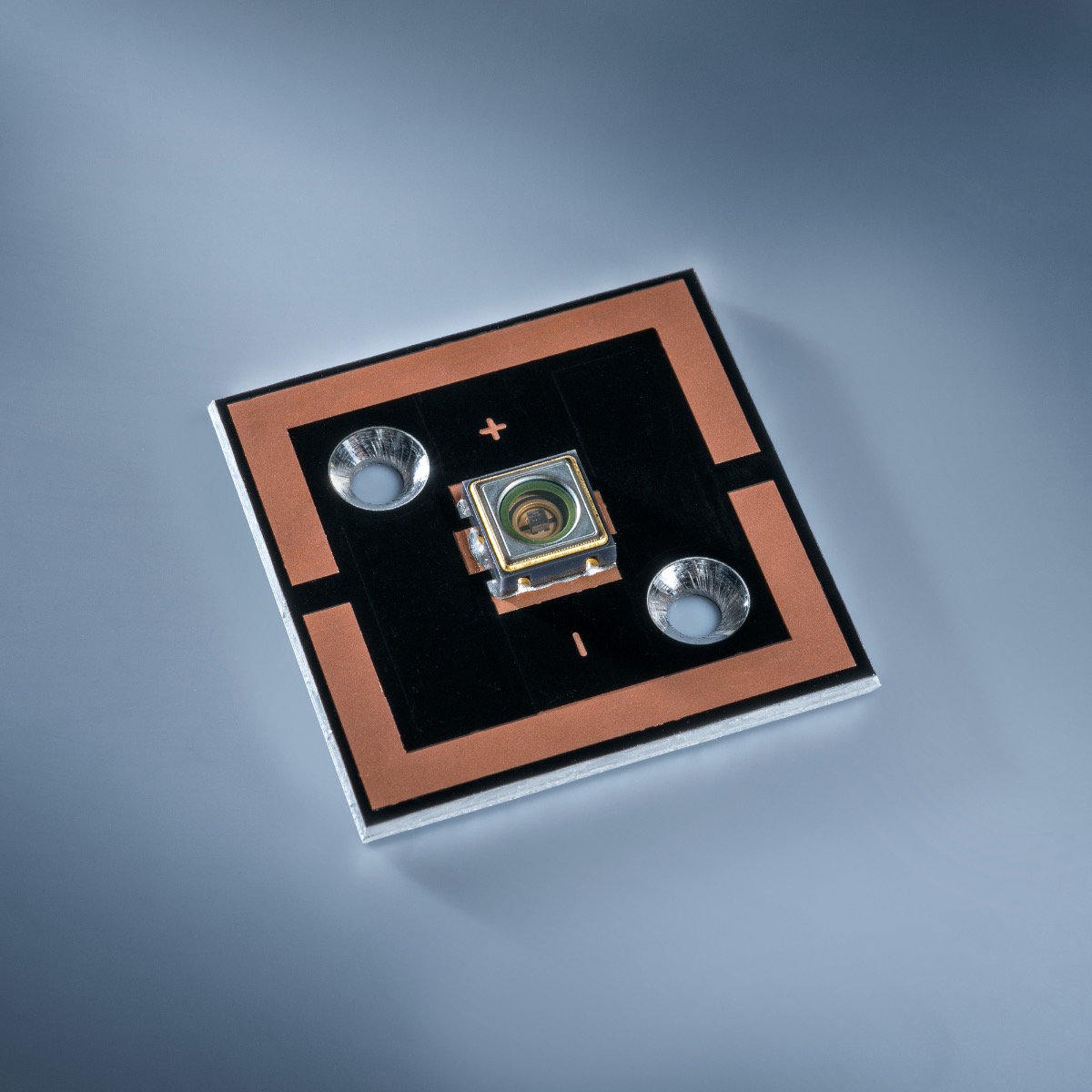

5. In a very interesting study11 from 2012, a combination of wavelengths from one 365nm, 10mW UVA LED and one 280 nm, 1.69 mW UVC LED, both from Seoul Semiconductor successfully disinfected of microorganisms 500 ml of waste water in under 60 minutes. Study was conducted on Mesophilic bacteria and Fecal enterococci.

These studies and others show that UVA radiation can also kill 99% of all bacteria or viruses (including COVID-19) with the condition of longer exposure or fluence than of UVC radiation.

All the above studies from 2007-2012 where conducted with UVA LEDs that irradiate the test surface or liquid from short distances because of the limited UV power of LEDs available at the time of the research.

By 2021 the UV power of UVA LEDs has increased exponentially and practical application of the results is now possible:

- NCSU033C LED from Nichia has a radiant power of 750mW at 365nm for 6.8x6.8mm in size

- Nichia NVSU233B has 1450mW

- Nichia NVSU333B has 4900 mW.

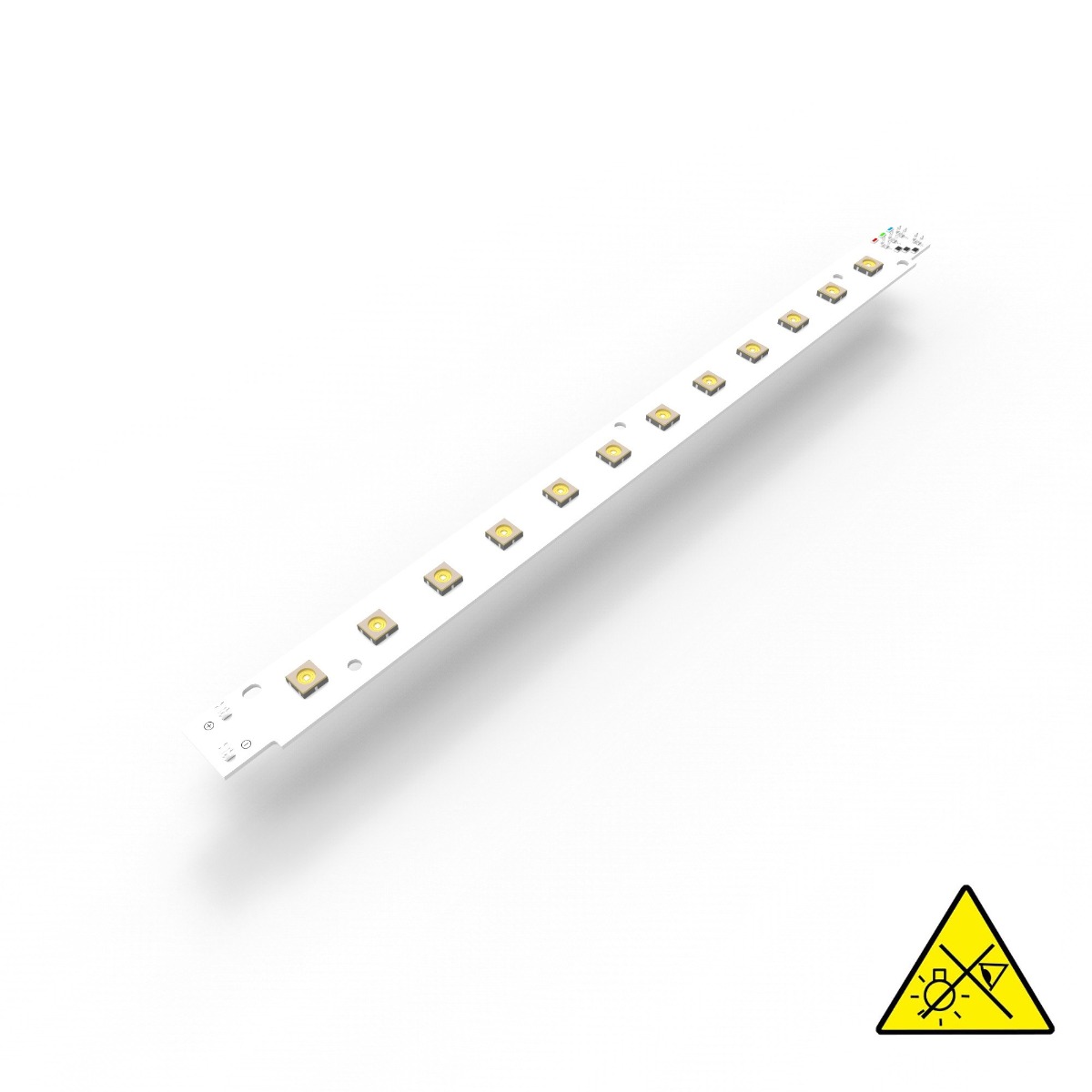

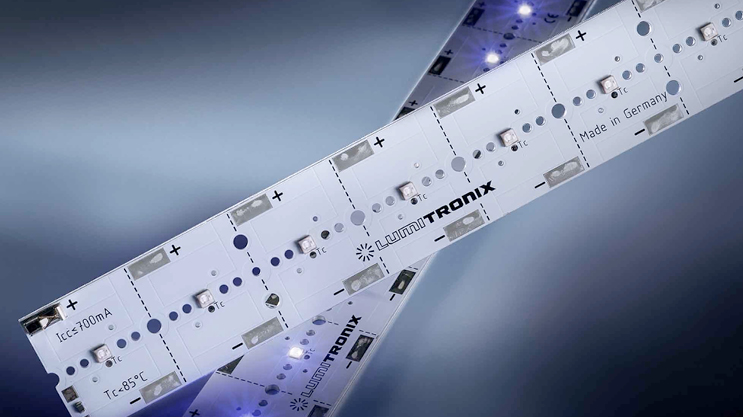

With their small size, UVA LEDs can be placed in linear module, such as the NVSU233B PowerBar with more than 12000 mW of UV radiant power for only 28 cm of length. At such level of radiation power with narrow spectrum, combined with the precision of optics technology and easy to control out via current limitation the new application of continuous disinfection is practical and can become widespread.

UVC LEDs also have seen progress, with typical radiant power at 50 to 100 mW, from LEDs such as Nichia NCSU334A (55 mW typical at 350mA). However, they still have too low radiant power for disinfection of rooms or even work surfaces. Possible applications for UVC LEDS are UV spotlight devices for disinfection at short distance or in fixtures in combination with UVA LEDs.

Continuous disinfection with 365nm UVA LEDs

The idea of continuous disinfection comes from the scientific fact that radiation at safe level for people can still kill viruses and bacteria.

|

“<8 hours & 3W/m2: up to 99% eradication of Staphylococcus aureus and Escherichia coli12”

“<8 hours & 3W/m2: up to 99% eradication of Staphylococcus aureus (MRSA), Candia auris, virus Phi X174 ,virus MS-213”

|

According to the IEC Standard 62471:2006, ‘Photobiological Safety of Lamps and Lamp Systems’ that gives safety thresholds for near-UV (UV-A; 315–400 nm) and far-UV (actinic; 200–400 nm), exposure at near-UV radiation, including 365nm, on the skin or at the eyes is safe for a period of up to 8 hours if the irradiance is limited to 10 W/m2. For far UV, the safe actinic-weighted irradiance limit is only 0.001 W/m2, also for 8 hours.

|

A system for continuous disinfection can be easily build with 365nm UVA LEDs that respect the 10 W/m2 safety threshold and function for a maximum of 8 hours per day.

Example:

365 nm UVA LEDs with 40W radiant power are placed inside a luminaire at room height of 2.5m and function 8 hours per day. The UVA radiation at 1.9m from the floor (height of a typical tall person) will be less than the 10 W/ m2, below the safety threshold for exposure up to 8 hours per day. The UVA LEDS will disinfect the work areas at 80-100 cm from the floor with irradiance of approximately 3 W/m2 , which has been proven to be effective to kill up to 99% of virus and bacteria.

|

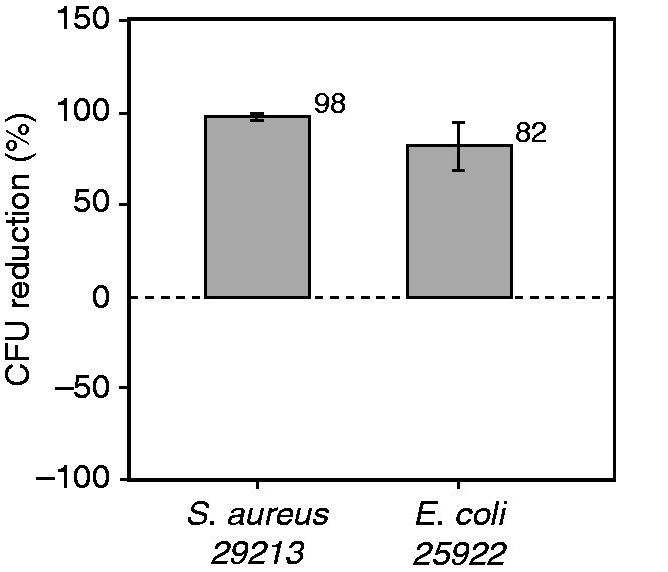

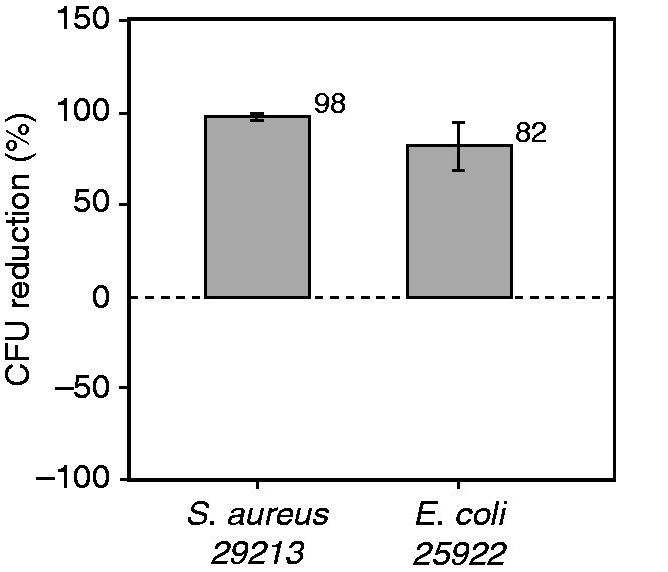

The continuous disinfection with 3 W/m2 irradiance from 365nm UVA LEDs has been proven to be effective, safe and easy to implement in a 2019 study12 published in the USA academic journal Lighting Research & Technology. The research found that the exposure to 365nm UVA radiation of only 3W/m2 at workplace height for 8 hours each day is safe for humans but will kill pathogens.

UVA LEDs where installed in ceiling luminaires, in patient rooms at the Memorial Beacon Children’s Hospital in South Bend, Indiana, USA, and functioned 8 hours per day with a irradiance of 3W/ m2 at workplace height. The UVA light was directed at the sink and counter areas, where the highest risk of infection exists.

Effectivnes of continuous disinfection was tested in these areas. Results show a reduction of up to 98% of the pathogens such Staphylococcus aureus and Escherichia coli.

A follow up study in a 2020 edition of the the American Journal of Infection Control13 found similar results of reduction from 3W/ m2 irradiance on the presences of pathogens such as methicillin-resistant Staphylococcus aureus (MRSA), Candia auris, the enveloped virus bacteriophage Phi X174(ATCC 13706-B1) and the nonenveloped virus bacteriophage MS-2(ATCC 15597-B1).

A follow up study in a 2020 edition of the the American Journal of Infection Control13 found similar results of reduction from 3W/ m2 irradiance on the presences of pathogens such as methicillin-resistant Staphylococcus aureus (MRSA), Candia auris, the enveloped virus bacteriophage Phi X174(ATCC 13706-B1) and the nonenveloped virus bacteriophage MS-2(ATCC 15597-B1).

Such studies create vast possibilities for the use UV LEDs for disinfection or sterilisation. Continuous disinfection with less than 10W/m2 with 365nm UVC LED light fixtures, faster disinfection with higher but controlled amounts from of UVC or UVA LEDs, or a combination of both are just some of the possibilities. More research about the effects on pathogens should also be made in order for this method to become standard, recommended, medical practice.

Continuous disinfection with near-UVA 405nm violet LEDs

The technological progress of LED techology in the last decade is actually higher for white and colors of the visible spectrum, including the near-UVA violet color of 405nm. With the market for LEDs with visible light being much bigger their prices are considerable lower than UVA or UVC LEDs.

Continuous disinfection fixtures with 405nm violet LEDs is also effective, easy to implement and was researched sooner. One of the first studies, as detailed in the American Journal of Infection Control14, happend between October 2015 and October 2017 at Maury Regional Health Center, a 255-bed regional hospital in Columbia, Tennessee, USA.

A ceiling-mounted lighting system measuring 2 ft x 4 ft with 405nm violet UV LEDs where installed in two operating rooms (ORs), with an irradiance level of 5-6 W/m2 (0.498 mW/cm2 to 0.558 mW/cm2) at workplace level15.

The study focused on measuring the infections in the two ORs between the previous period when manual cleaning was used to the current period, with augmented disinfection with the violet light 405nm system.

While violet light is much safer than UVA, it is visible light that impacts the color redention of the lighting installation, thus the violet LEDs only function when the rooms where not in use.

At the end of the study, statistically significant reduction was discovered, with only 3 infections compared to an anticipated 12 infections that resulted from a prediction based on the previous period. The conclusion was that a potential 9 infections were prevented. The results where so promising that lighting systems with violet LEDs for continuous disinfection are already installed in operating rooms in more than 20 hospitals across the USA16.

References:

- Far-UVC light: A new tool to control the spread of airborne-mediated microbial diseases: https://www.nature.com/articles/s41598-018-21058-w

- News article Coronavirus: Robots use light beams to zap hospital viruses https://www.bbc.com/news/business-51914722

- Predicted Inactivation of Viruses of Relevance to Biodefense by Solar Radiation https://www.ncbi.nlm.nih.gov/pubmed/14631830

- Stability of SARS coronavirus in human specimens and environment and its sensitivity to heating and UV irradiation. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC1280232/

- Inactivation of Middle East respiratory syndrome coronavirus (MERS-CoV) in plasma products using a riboflavin-based and ultraviolet light-based photochemical treatment. https://www.ncbi.nlm.nih.gov/pubmed/27805261

- UV Faq: http://www.iuva.org/UV-FAQs

- Sterilization Using 365 nm UV-LED https://www.semanticscholar.org/paper/Sterilization-Using-365-nm-UV-LED-Yagi-Mori/ee8484bf684b2077358508df00e9a42289f9f09f

- New water disinfection system using UVA light-emitting diodes https://sfamjournals.onlinelibrary.wiley.com/doi/pdf/10.1111/j.1365-2672.2007.03464.x

- Development of a new water sterilization device with a 365 nm UV-LED https://www.researchgate.net/publication/5867444_Development_of_a_new_water_sterilization_device_with_a_365_nm_UV-LED

- Enhanced germicidal effects of pulsed UV-LED irradiation on biofilm https://sfamjournals.onlinelibrary.wiley.com/doi/pdf/10.1111/j.1365-2672.2010.04850.x

- Effect of coupled UV-A and UV-C LEDs on both microbiological and chemical pollution of urban wastewaters https://hal.archives-ouvertes.fr/hal-02069416/file/CHE%20HAL%202%20OK.pdf

- An assessment of a hybrid lighting system that employs ultraviolet-A for mitigating healthcare-associated infections in a newborn intensive care unit https://journals.sagepub.com/doi/full/10.1177/1477153520904107

- American Journal of Infection Control Efficacy of an ultraviolet-A lighting system for continuous decontamination of health care−associated pathogens on surfaces https://www.ajicjournal.org/article/S0196-6553(19)30746-1/pdf

- Influence of a visible-light continuous environmental disinfection system on microbial contamination and surgical site infections in an orthopedic operating room https://www.ajicjournal.org/article/S0196-6553(18)31146-5/pdf

- Shining a light on continuous disinfection: https://indigo-clean.com/assets/pdfs/Shining-a-Light-on-Continuous-Disinfection_CRTM_June-2018.pdf

- Website of manufacturer of violet light continuous disinfection system https://indigo-clean.com/who-is-using-it.php

Disclaimer: This article is for informative purpose only. The accuracy of the facts, findings an results presented are as good as the research results that are quoted above and the understanding of the author. Ledrise, nor the author of this article, are to be held responsible for the results of using UV disinfection/ sterilization based on information in this article.

If there are inaccuracies in this article there are solely by error. We appreciate all feedback in this matter.

Lumistrips EN

Lumistrips EN Lumistrips US

Lumistrips US Lumistrips ES

Lumistrips ES Lumistrips PT

Lumistrips PT Lumistrips ITA

Lumistrips ITA

The time needed for UV to kill bacteria or viruses is depended on the radiation wavelength. UVC radiation will require the shortest time, as low a few seconds while UVA with the same irradiance will disinfect in minutes or hours.

The time needed for UV to kill bacteria or viruses is depended on the radiation wavelength. UVC radiation will require the shortest time, as low a few seconds while UVA with the same irradiance will disinfect in minutes or hours.

A follow up study in a 2020 edition of the the American Journal of Infection Control13 found similar results of reduction from 3W/ m2 irradiance on the presences of pathogens such as methicillin-resistant Staphylococcus aureus (MRSA), Candia auris, the enveloped virus bacteriophage Phi X174(ATCC 13706-B1) and the nonenveloped virus bacteriophage MS-2(ATCC 15597-B1).

A follow up study in a 2020 edition of the the American Journal of Infection Control13 found similar results of reduction from 3W/ m2 irradiance on the presences of pathogens such as methicillin-resistant Staphylococcus aureus (MRSA), Candia auris, the enveloped virus bacteriophage Phi X174(ATCC 13706-B1) and the nonenveloped virus bacteriophage MS-2(ATCC 15597-B1).